Custom Pistons

Race Winning Brands offers many possibilities to make custom made pistons to specifications you want. Both Wiseco and JE are offering this service. Our sales team is more than happy to inform you about the possibilities.

Did you know that Race Winning Brands can make forged pistons to your specifications? From 4 pieces we can manufacture a custom made forged piston that suits your application best. The design of the piston, the ring package, pin and clips will be matched for the perfect fit and performance. And… it is very easy to order. Just contact one of our piston specialists by using our contact form.

What sets us apart from the competition?

All pistons are forged and manufactured at our factories in the USA.

Custom Piston Features:

Race Winning Brands has vast experience engineering and manufacturing all types of pistons. We produce pistons for every form of racing: Drag Racing, Road Race, Rally, Autocross, Off Road, Land Speed, and others. You name it, we make the best piston for it!

The following features are available:

- Fully CNC Machined Piston

- 2618 Low-Silicon or optional 4032 High Silicon material available on some applications

- Specialized ring grooves, such as Dykes and exact tolerance ring grooves

- Specialized machining features, such as – 3D, undercrown, and special operations milling

- Specialized ring sets for high horsepower forced induction applicationsPrecision Machined CNC Ring Grooves

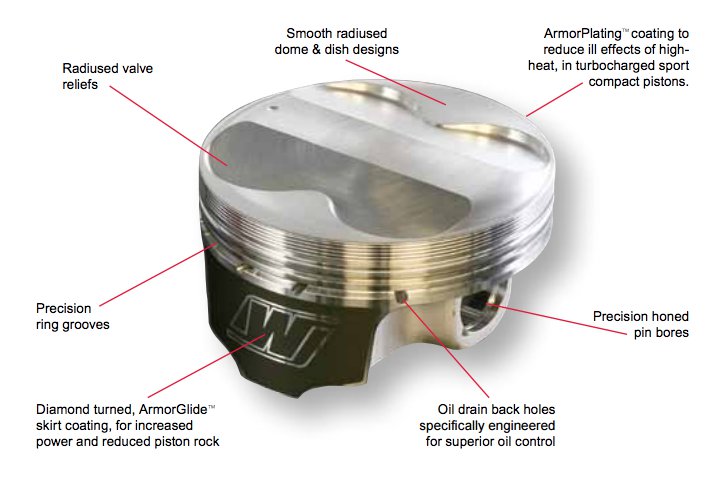

- Diamond Turned Skirts

- Radiused Valve Reliefs

- Single Forced Pin Oilers

- Pick Lock Grooves (for use with wire locks)

- Gas ports (vertical and horizontal)

- Custom Forging for large volume production available (call for details)

- Full Round design forging with bottom reinforcing band for extreme HP applications

- Modern Strutted style forging available for the ultimate in strength and weight savings

Piston Machining Options

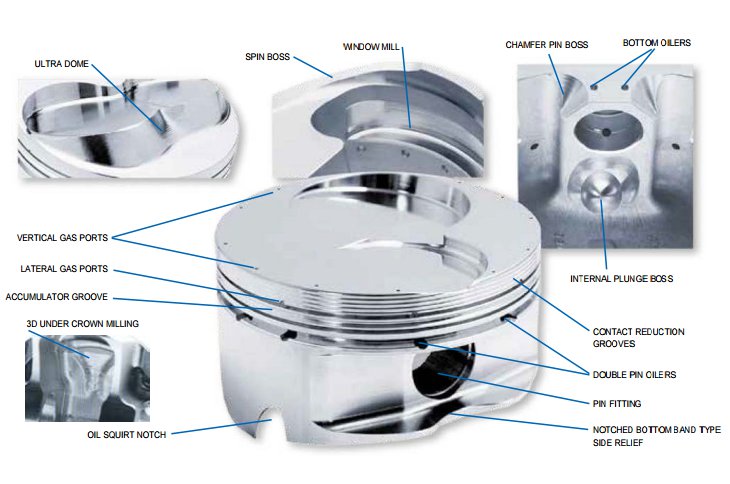

Ultra Crown Dome/inverted dome

The ultra Crown machining process allows incredibly precise dome to cylinder head tolerances. By mapping the exact shape of a piston or cylinder head, optimum compression and quench characteristics can be achieved.

3D Under Crown Milling

The under Crown machining process allows for uniform deck thickness, therefore creating a lighter and more durable piston.

Vertical Gas Ports

Vertical holes in the deck of the piston, allows combustion pressure to directly enter behind the top ring on the power stroke, thus pressurizing the area behind the top ring for greater ring to cylinder wall seal. During the rest of the cycle, the ring has normal tension for reduced friction. (Most commonly used for drag race applications).

Lateral Gas Ports

This process mills slots into the top of the top ring groove and provides a pathway for combustion pressure to get behind the top ring. This process helps to increase ring seal and is most common in circle track applications

Ultra Groove

ultra Groove is a special ring groove machining process that provides near perfect groove flatness and surface finish. Tolerances are held to millionths of an inch.

Plunge Boss & Chamfer Pin Boss

Machining process that removes additional material for added weight savings.

Pin Boss & Window Milling

In certain applications window milling will remove a significant amount of weight from the skirt of the piston while maintaining its strength and integrity. Spin Boss refers to machining on the bottom of the pin boss, which removes weight where it is not needed for strength.

Contact Reduction Grooves

The purpose of machining these grooves is to reduce the amount of contact area against the cylinder wall when the piston “rocks over”. Contact reduction also serves to disrupt the flame travel into the crevice area thus helping to reduce detonation.

Accumulator Grooves

An accumulator groove is machined into the land between the top and second ring. It provides additional volume where residual combustion gases that have “blown by” the top ring can collect. This additional volume helps to reduce pressure between the top & second ring, thus aiding in top ring seal and minimizing ring flutter

Double Pin Oilers

Double Pin Oilers deliver twice the amount of oil to the wrist pin as compared to the standard single pin oiler.

Pin Fitting

The pin bore is precision honed to attain an exact pin clearance. Clearances typically range from .0003 to .0010 between the wrist pin and pin bore

Oil Squirt Notch

Notching can be done on pistons for motors with oil squirters, or to avoid contact between pistons and/or pistons and crankshaft.

Bottom Oilers

This process machines one or two holes into the bottom of the pin boss to assist in splash pin lubrication.

Tulip Valve Pockets

Most commonly used on Hemi and motorcycle engines, this process leaves a raised area on plunged valve pockets to achieve maximum compression.

Piston Coatings

Thermal barrier crown coating

Applied to the top of the piston and is designed to reflect heat into the combustion chamber, there by increasing exhaust gas velocity and greatly improving scavenging potential. The .0015” thick coating can also assist in extending piston life by decreasing the rate of thermal transfer.

Tuff skirt coating

Our pistons’ trademark coating that is a lubricating, anti-friction/anti-wear coating applied to the piston skirt only. unlike our standard Skirt Coating, Tuff Skirt will not wear and is designed to withstand many different types of endurance applications, similar to those commonly found in NASCAR. Buildup is .0005” per surface and finished diameter of skirt should include the coating buildup.

Anodized ring groove coating

Reduces wear and material transfer between the ring and groove. Shown to be very durable in maximum effort, high endurance applications. Appropriate manufacturing allowances applydup.

Koolkote

Is an aerospace quality hard anodize applied to all surfaces of the piston with a buildup of .001. This coating is designed for use in nitro-methane engines such as Top Fuel Drag Racing to endure the corrosive effects of this type of fuel. It will withstand greater txemperatures and will not flake, chip or peel. This coating does alter the heat transfer and expansion characteristics of the piston. Consult the JE Pistons technical department for specific applications. Manufacturing allowances are required on all surfaces.

Custom Piston Ordering Tips

Custom piston order form available.

- Consult a Race Winning Brands Europe B.V. sales rep by our contact form

- Supply as much information regarding specifications as possible. It is very important for us to know quantity, motor type, induction, power levels, RPM, and usage (i.e. – street, drag race, road race, etc.). Our piston specialists will walk you through the process to be sure you get the piston you need.

- Minimum order quantities apply. Ask a salesperson for details.

- Remember, Race Winning Brands Europe B.V. personnel are always ready to help. Please call today!